-

Home

-

How We Build / Q & A

How We Build / Q & A

How was Cornhole Pro started?

Cornhole Pro started out as a hobby in our garage in 2016 and has grown beyond our dreams. We have shown our four kids that anything is possible with prayer, hard work, and a quality product.

When we started our business it was our goal to offer a solid product that we would be excited to receive ourselves, one that would bring families together and last for years.

What makes Cornhole Pro boards different than others?

- Made to ACL tournament specs. Board dimensions: 24" X 48" (regulation size)

- All tops are 3/4" Baltic Birch (not pine). Made entirely from birch plies with exterior glue and no core voids or face patches.

- High resolution images are printed directly on the wood (no wraps, decals or hand painting

- Routered edges on the top of the board

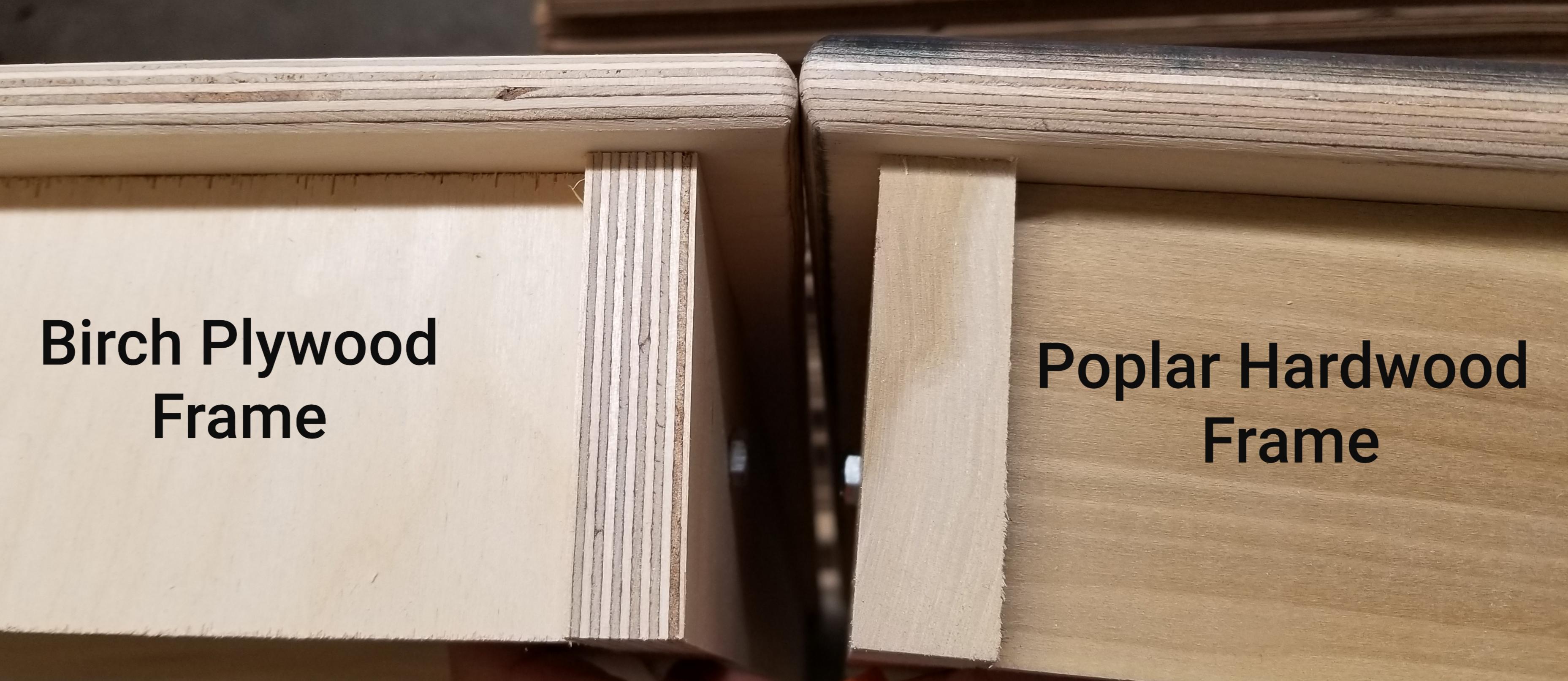

- Hardwood Poplar 3" frame with center brace for added support (no plywood or pine) on both standard and pro series boards

- Hardwood Poplar 3" legs with center brace for added support (no plywood or pine) on both standard and pro series boards. Legs are attached to frame with bolts.

- Pocket holed, screwed and glued with titebond II

- 6 inch hole (centered 9 inches from the back edge of the board)

- 3 smooth spray finish coats of water based exterior spar urethane on top. 2 coats on the frame and legs

- If you have custom artwork, it is approved before the boards are printed

- Made in Minnesota

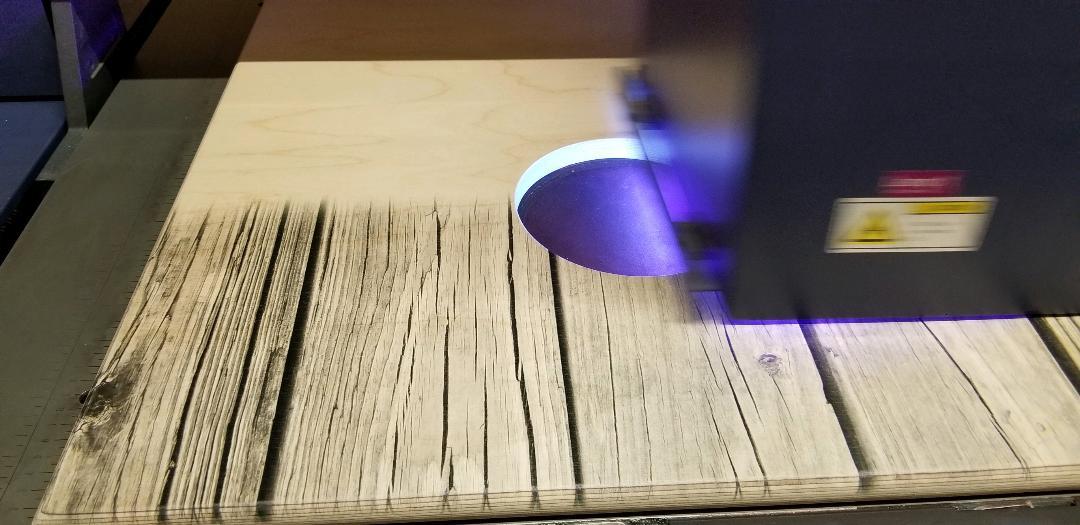

What is UV direct printing?

UV printing is a form of digital printing that uses ultra-violet lights to dry or cure ink as it is printed. As the printer distributes ink on the surface the UV lights follow close behind, curing - or drying - the ink instantly. Because the UV lights cure any printed ink immediately, the dots of wet ink do not get a chance to spread out once printed, resulting in much finer detail. In addition, UV cured inks are weather-resistant and offer increased resistance to fading. This curing process is more environmentally friendly as it produces few VOC’s, odor, and heat.

What is CNC cutting important?

It cuts materials with speed and precision!

Why does Cornhole Pro use 3B Baltic birch (B/BB) instead of pine, maple or oak?

- Higher quality than standard birch plywood.

- Made entirely from birch plies with exterior glue for more stability. No veneer core.

- Has no core voids.

- Uniform light color.

- No plugs, biscuits or open cracks/splits on the top of the board.

- Birch is harvested much slower than other woods, causing the growth rings to be smaller for less warping in finished products.

Why does Cornhole Pro use poplar wood for the frame instead of birch or pine?

Poplar is a hardwood that is dent-resistant and is usually a higher quality of wood. Poplar can handle heat and water better than pine, making poplar more resistant to warping. Poplar is a solid wood produced from slabs of wood that are sawn from logs and then kiln dried. The drying process not only reduces the moisture content of the wood but also increases its strength and dimensional stability.

What does Cornhole Pro use to finish the boards?

We apply 3 smooth spray finish coats of water based exterior spar urethane on top. 2 coats on the frame and legs.

Why we choose Varathane water based exterior spar urethane?

- Superior poly protection for exterior wood surfaces

- Self leveling, smooth clear finish with max top coat durability

- Fast dry poly does not yellow over time

- Provides maximum UV protection to guard against sun damage.

- Varathane keeps your wood looking great longer.

What is a routered edge?

It rounds the hard edge of a board leaving a smooth finished edge

The woodgrain images look three dimensional. Is the top a smooth flat surface?

YES! Although some images look like an uneven surface (split face) the woodgrain is printed on a sanded birch top but still gives the boards a realistic rustic look.

There are no products listed under this category.